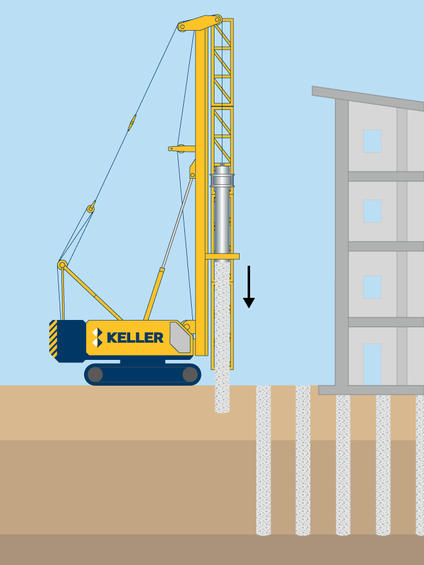

Driven precast piles are installed using impact or vibration hammers to a design depth or resistance.

Common uses

Can be used for all types of construction, particularly in aggressive soil conditions

Well suited to sites where the ground conditions are highly variable as they are driven to a set or pre-determined resistance

A good foundation choice when you have very thick layers of soft soil and/or a high water table that would be problematic for a traditional drilled pile

Large pile sizes can be used for: wind turbines and pylons, river bridge foundations, bridge abutments and piers, marine construction

Process

Driven piles can be made of precast concrete or steel H-piles. In some cases, pre-drilling may be necessary in dense soil to allow the pile to reach design depth. They can be installed in one length or jointed for deeper piles.

Specialist Contact | Simon Thompson - simon.thompson@keller.com - +44 (0)7748 968391

Advantages

No spoil so often the most cost effective piling solution for contaminated or brownfield sites

Rapid follow-on construction

Extensive range of pile sizes

Piles are pre-manufactured to factory standards, the required length and standard conformity

Piles may be installed to significant depths > 40m

Unaffected by ground water

Widely used and suited to most ground conditions

Quality assurance

Keller has access to an extensive selection of pile sizes to ensure an optimum design solution and can draw on extensive experience and resources to ensure successful project delivery.

We also use the most up-to-date, enclosed hydraulic hammers, which keep noise disturbance to a minimum..