Our sister company, Phi Group, offers a range of retaining wall and reinforced soil systems including the Permacrib gravity system; the Andacrib modular precast concrete crib system; and Gabions that use steel mesh cages filled with a large angular stone.

Common uses

Process

Whatever the size of your project, our in house engineers can provide a quotation and technical appraisal for a retaining wall to suit your specific requirements. Different processes are used for different retaining walls.

Permacrib

Permacrib uses timber header and stretcher components to create a ‘timber cage’ which is then filled with a graded stone to create its mass. The gravity retaining wall principle means that the mass within the wall resists the applied forces. Consequently the higher the wall needs to retain, the deeper the structure needs to be. Permacrib has eight different model sizes ranging from header sizes of 600mm to 1650mm, so we can provide the most economic structure possible.

We can introduce planting bags within the Permacrib wall to enable planting of the front face, so an ever softer finish can be achieved. Corners, curves and angle changes are also very easy to incorporate into the wall design.

Andacrib concrete crib retaining walls

Once the starter units are cast on the foundation, the concrete units simply interlock together to form the framework which is then infilled and backfilled with a free draining granular material.

Planting bags may be installed within the Andacrib to allow feature landscaping of the Andacrib face.

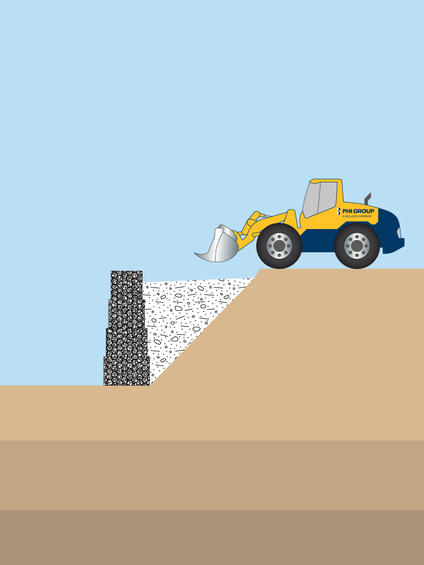

Reinforced Soil

Reinforced soil slopes and structures are typically used where levels are being raised on site, and steep slopes or vertical structures are required, therefore increasing the amount of flat available land to develop. Material is compacted around layers of reinforcement to form a reinforced soil mass. The facing is then chosen based on slope angle, maintenance and aesthetic considerations.

Textomur reinforced soil system

A combination of steel mesh ‘formwork’ and geogrid reinforcing elements are used to form engineered slopes of up to 70 degrees. Textomur can have topsoil placed inside the front face that will assist vegetation in establishing, or have gabion stone placed inside the front face to give a maintenance free solution.

Vertical reinforced soil systems

Where vertical structures are required there are several facing options, with a modular block being the most popular. Concrete panel faced structures are widely used on infrastructure projects such as bridge abutments and wing walls.

Gabions

Gabions are manufactured from either woven wire or, more commonly a welded mesh steel. The welded mesh gabions offer a more rigid front face to achieve a more uniform finish. Design life can be from 50-120 years depending on the corrosion protection and whether the gabions are pvc coated.

Structure depth has a big bearing on the cost of the gabion wall. As the infill stone is large and angular, the density of this fill will be lower than that of the Permacrib or Andacrib walls that use a 75-40mm stone. This means that a gabion structure will be deeper than a Crib structure would be, therefore more expensive in terms of infill material required.

Specialist Contact | Rob Torrington - [email protected] - +44 (0)7753 573762