The Thames Tideway is a 25km long tunnel running mostly along the line of the River Thames through central London. It will provide capture, storage and conveyance of almost all the combined raw sewage and rainwater discharges that currently overflow into the river. The Blackfriars Bridge Foreshore worksite included the construction of a drop shaft for a Tunnel Boring Machine.

The project

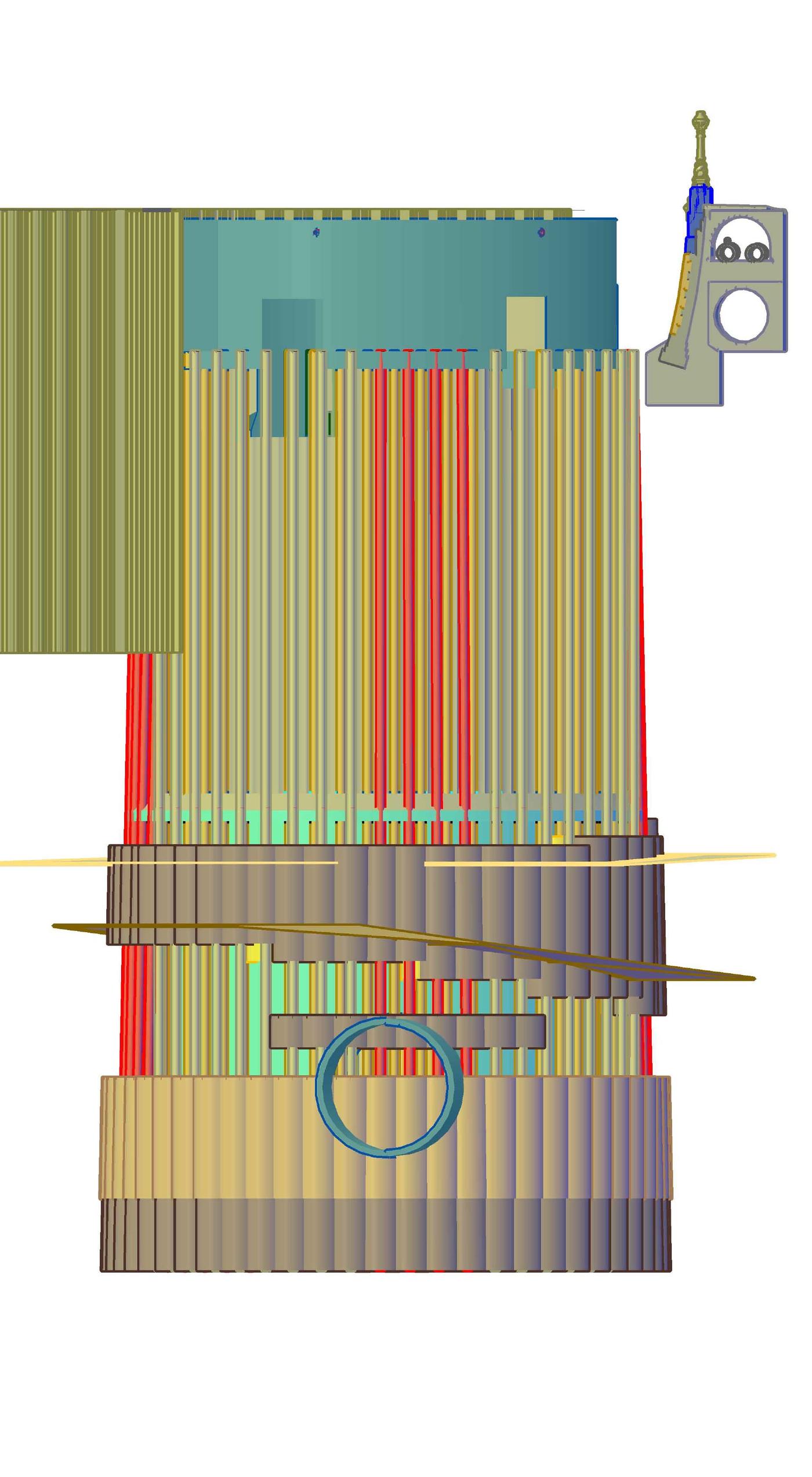

The online 55m deep, 22m diameter sprayed concrete lined (SCL) drop shaft for a Tunnel Boring Machine (TBM) being built in the River Thames needed to be watertight. Jet Grouting was proposed for two reasons:

• To stabilise granular soils around TBM intervention

• To stabilise granular soils for the open face SCL shaft construction

In both cases, the primary means of ground stabilisation was dewatering.

The challenge

To form fully interlocking jet grouted columns 52m deep, in varying ground conditions from within a cofferdam situated in the River Thames.

The solution

Following successful trials on a previous shaft, Keller formed 2.6m diameter interlocking columns at 52m depth, using specialist in-house jet grouting equipment, working 24/7 for 15 weeks to accelerate the programme. Keller deployed specialist expertise from several different business units to successfully complete the works.