Minipiles are a deep foundation element constructed using high-strength, small-diameter steel casing and/or threaded bars.

Common uses

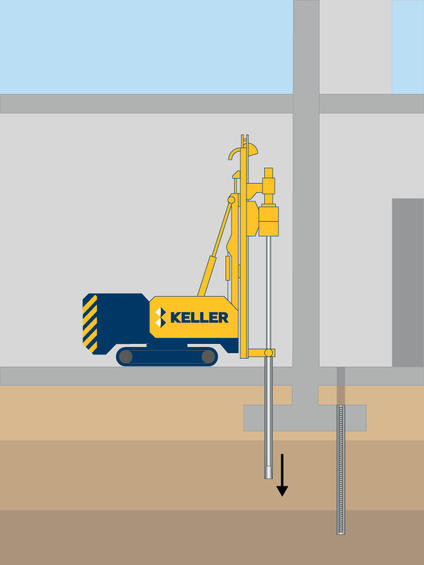

Process

The casing, with a diameter generally in the range of 200-600mm is advanced to the design depth using a drilling technique.

Reinforcing steel, typically an all-thread bar, is inserted into the minipile casing and high-strength cement grout pumped in. The casing may extend to the full depth or end above the bond zone with the reinforcing bar extending to the full depth.

Capacities vary depending on the minipile diameter and subsurface profile but compressive capacities of more than 1000kN have been achieved.

Specialist Contact | Anthony Lucas - [email protected] - +44 (0)7908 502122

Advantages

Quality assurance

Keller has vast minipiling experience in all ground conditions with the ability to design in-house based on subsurface conditions, structural requirements and environmental limitations.