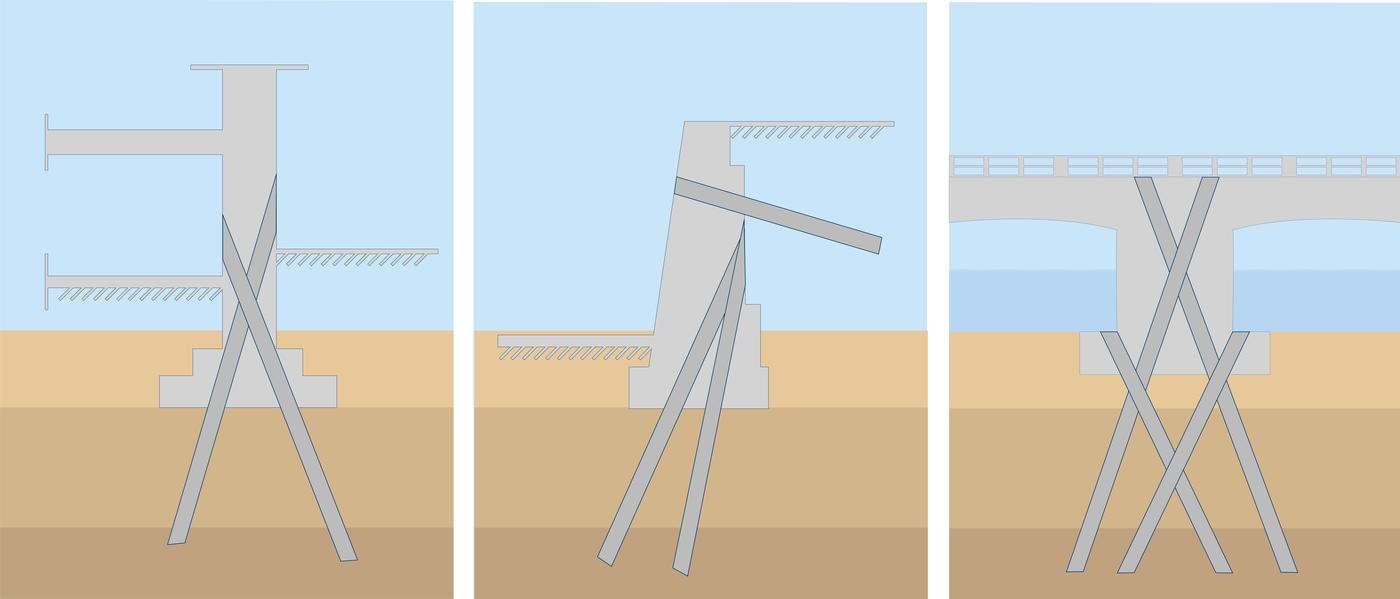

Pali Radice (literal translation ‘Root Pile’ from the Italian) is a versatile foundation system using small diameter cast in situ bored piles, developed in Italy in the 1950s. It has been extensively employed as an underpinning/stabilisation system for strengthening existing foundations which are settling or are required to support increased loads.

Common uses

Process

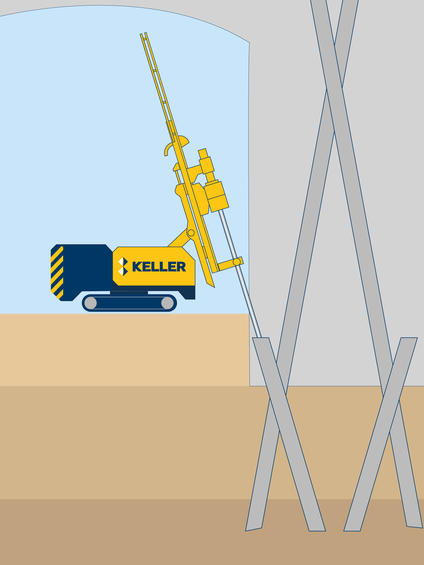

The piles are formed using specialist rotary drilling rigs (so that virtually no vibration is transmitted to the structure) by boring a temporary steel casing to depth using a special cutting bit.

A drilling fluid (usually water) is circulated through the casing so that it cools the cutting bit and returns outside the casing, transporting the arisings with it to the settlement tanks.

To enable the drilling rigs to operate in restricted headroom, short lengths of casing are coupled together during boring.

These specialist rigs are also narrow enough to fit into tight spaces and many are electric-powered, enabling them to operate safely where conditions are limited in other ways.

Specialist Contact | Anthony Lucas - [email protected] - +44 (0)7908 502122