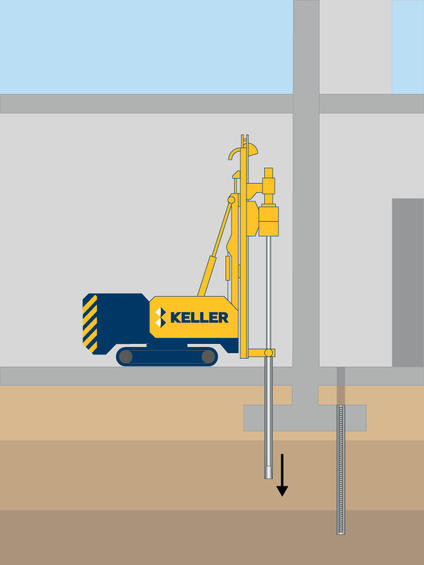

In restricted access situations, where large, heavy conventional plant cannot be used, we provide a choice of piling systems such as continuous flight auger, cased CFA, rotary bored, drilled rock socket or driven. A number of our restricted access rigs are able to enter buildings via a normal service entrance or a standard doorway.

Common uses

Process

The casing, with a diameter generally in the range of 100-1080mm is advanced to the design depth using a drilling technique.

Reinforcing steel, typically an all-thread bar, is inserted into the minipile casing and high-strength cement grout pumped in. The casing may extend to the full depth of the pile or finish short of the bond zone with the reinforcing bar extending to the full depth.

Capacities vary depending on the pile diameter and subsurface profile but compressive capacities of more than 2000kN have been achieved depending on ground conditions.

Specialist Contact | Anthony Lucas - [email protected] - +44 (0)7908 502122

Advantages

Quality assurance

Keller has vast restricted access piling experience in all ground conditions with the ability to design in-house based on subsurface conditions, structural requirements and environmental limitations.