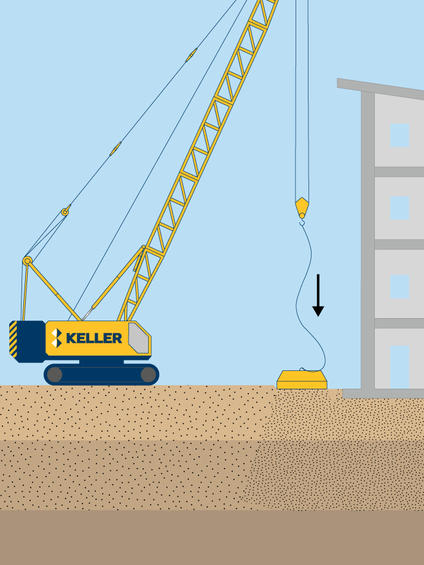

Dynamic compaction involves the controlled impact of a crane hoisted weight, of around 10-12 tonnes, falling in a pre-determined grid pattern to improve loose, granular and mixed soils and fills.

Common uses

Process

Dynamic compaction is a ground improvement technique that densifies soils and fill materials by using a drop weight. The ground is subjected to repeated surface tamping using a heavy steel and concrete weight. Typically the tamper weighs between 10 and 12 tonnes, dropping in free fall from heights of up to 10 metres. The tamper is dropped a set number of times on a grid pattern over the site to form a pass. Two or three passes may be required on a site, dependent on soil type and condition. The imprints formed at each drop position are infilled with granular material after each pass.

Specialist Contact | Derek Taylor - [email protected] - +44 (0)7769 654163

Advantages

Quality assurance

Typically, in situ testing by borehole or static cone penetrometer, allied with measurement of print volume and site surface settlement is performed during the dynamic deep compaction.

The treatment pattern, energy level, number of passes and phasing of passes must be designed to take into account the soil conditions, type of development and required bearing capacity and settlement characteristics. It is essential to have a thorough understanding of the soils prior to treatment, and to maintain very close control during all phases of the work. Typically, insitu testing by borehole or static cone penetrometer, allied with measurement of print volume and site surface settlement is performed during the dynamic deep compaction contract.

Watch our video of Skelton Gate